Problem definition

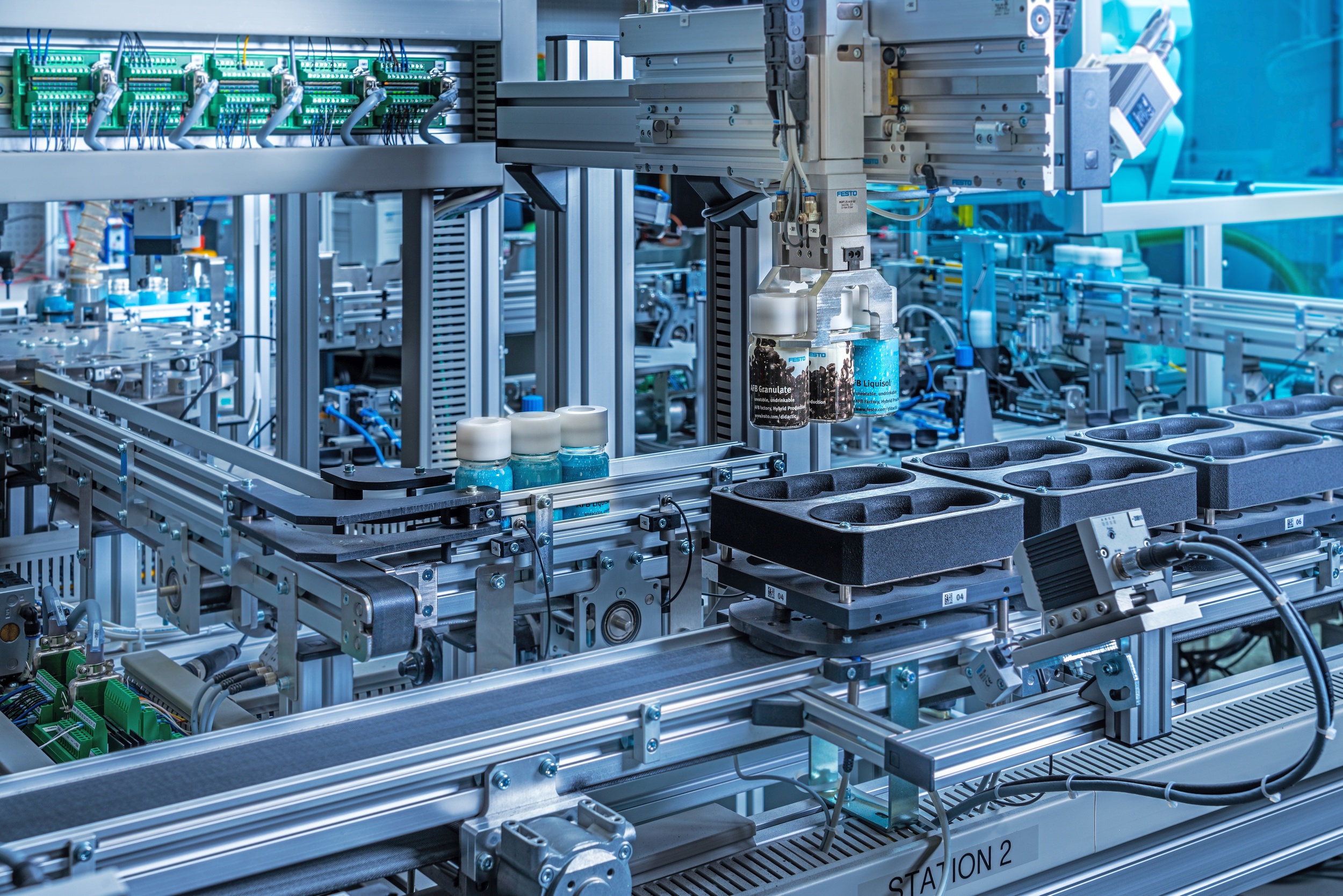

At a demo plant that produces, delivers and recycles piece goods, the system sometimes comes to unexpected stops. The reasons are manifold and range from badly screwed on lids to a loose conveyor belt or missing compressed air at the robot arm. Holistic plant monitoring is therefore desirable.

Goal

Develop an AI-based system that learns the normal state of the plant and matches this state against the current plant state. If a fault is detected, it should be displayed on a mobile device.

Solution Expertise

First, data is collected to describe the normal state of the plant. Then, some tests are performed and potential error sources are identified. Based on this data, an AI is learned and benchmarking is performed. Finally, the AI is connected via OPC UA and the current results are streamed to a web application for the operators.

Test bed

Model factory at Fraunhofer IOSB

Competence Center AI Engineering

Competence Center AI Engineering